What is Thermography?

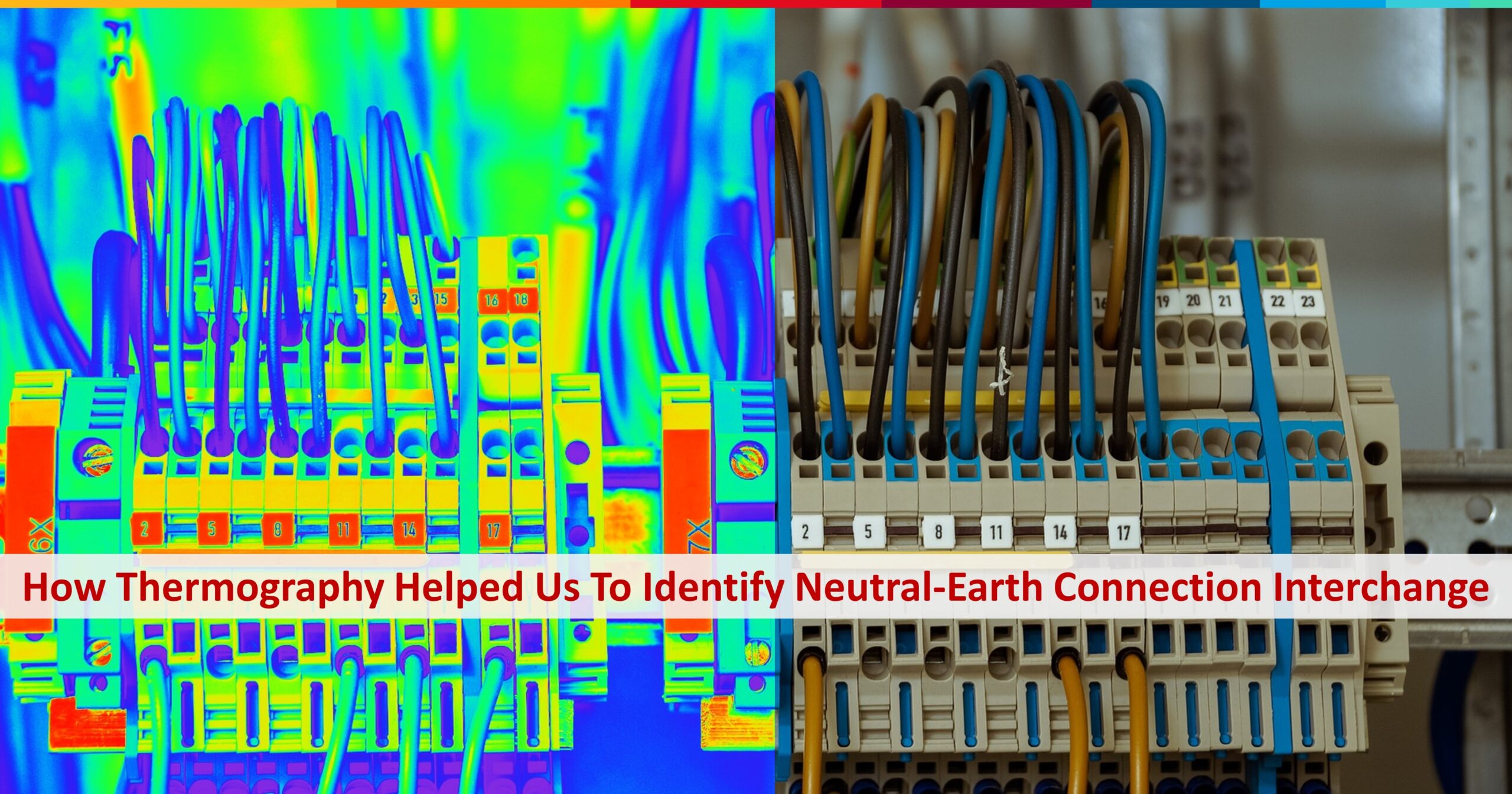

Infrared thermography is a diagnostic technology in which we can "see" and "measure" the thermal energy emitted from an object through images. With an infrared camera, we can capture thermal images without making direct contact with equipment. All objects emit infrared energy, known as a heat signature. A thermal imager detects and measures the infrared energy of subjects in front of it. The camera is capable of converting that infrared data into an electronic image that shows the apparent surface temperature of the object being measured. A thermal also incorporates a visible light camera which captures a standard image. This helps the comparison of the real image and thermal image.

The advantage of thermography is that it allows capturing thermal information from operating equipment from a safe distance. Infrared thermography is applicable for electrical, mechanical, thermal systems and even useful for civil structures. A regular infrared inspection can help keep the system operating safely and more efficiently. Thermography has a wide range of applications and we will discuss a peculiar case observed during one of the studies conducted by us.

Case Study

Typically, Infrared Thermography is conducted in electrical installation to find out hotspots in cable terminations, breakers, and bus bars. Improper connection, loose contact and overloading are common reasons observed in electrical installations leading to hotspots. The temperatures can go even a few hundreds of Degree Celsius.

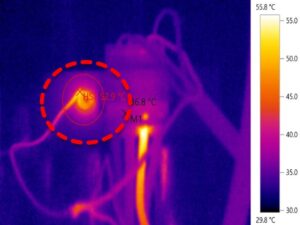

An electrical safety audit was conducted for one of our clients. Thermography of the electrical installation was a part of the study to identify hotspots. While inspecting a High Mast Lighting Pole, we had found a hotspot in the earth conductor, the temperature was 53oC. This situation is unusual, and we checked the current flowing through the conductor, which was about 10A.

Thermal & real image of the faulty area

After checking the current flowing through the earth wire with a clamp meter, we found that there is an issue in the electrical connection. The neutral conductor and earth conductor were interchanged while wiring. It is dangerous for both humans and property. Normally, it is not easy to notice such kind of strange cases without a thermal imaging camera. We recommended rewiring the cables to avoid hotspots and reduce any electrical safety risk in future.

Few things are very much important in Thermography for better results:

- Thermography should be conducted by an expert- As discussed above, we cannot conclude anything by seeing a thermal image. Only an experienced professional can understand the issue and give recommendations to resolve the problem. Interpretation of the thermal image is a key factor.

- Understating the system is important to find a better solution- When we see any hotspots or any unusual cases, it is very much essential to analyse the issue at the site itself to identify the root cause.

Thermography plays a vital role in reducing electrical fire accidents both in commercial and industrial establishments. AS per NFPA 70B (Recommended Practice for Electrical Equipment Maintenance), routine infrared inspections of energized electrical systems should be performed annually prior to shut down. More frequent infrared inspections, for example, quarterly or semi-annually, should be performed where warranted by loss experience, installation of new electrical equipment, or changes in environmental, operational, or load conditions.

Thermography is helpful in addressing unusual cases which might have been left unnoticed in visual inspection. This case study shows that even a mistake in wiring can be found out with the help of an experienced professional by infrared thermography. Make use of thermography to find faults in advance, reduce electrical safety risk, avoid downtime and save money.