Compressed Air Leak Audit

A Compressed Air Leak Audit identifies and quantifies leaks in your system, helping you recover lost energy, improve efficiency, and extend equipment lifespan. By detecting and tagging leaks, we provide actionable insights to reduce waste, lower costs, and enhance system reliability. eaks exists in joints, flanges, welds upto end use instrumentations.

Key Focus Areas

- Leak Detection & Quantification - Identifying leaks using ultrasonic detectors and estimating air loss.

- Tagging & Classification - Categorizing leaks based on severity and impact, with critical leaks marked for immediate repair.

- Pressure Drop Analysis - Evaluating pressure variations across the system to identify restrictions and inefficiencies.

- Flow & Energy Consumption Analysis - Measuring air usage to detect excessive losses.

- Air Demand & End-Use Assessment - Identifying unnecessary compressed air consumption.

Audit Deliverables

Leak Map & Tagging Report

Detailed documentation of leak locations and severity.

Extended Equipment Life

Preventing thermal stress, overheating, and inefficiencies that degrade industrial systems.

Repair & Maintenance Recommendations

Prioritized action plan for leak mitigation.

Best Practices for Leak Prevention

Strategies to maintain an efficient compressed air system

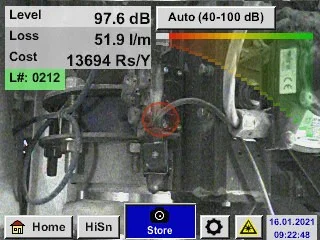

Fig (a): leakage identified in cement industry

(Ball joint)

Fig (b): leakage identified in cement

(union joint)

A well-maintained compressed air system (facility engaged in regular leak audit with post repairs) will have leaks less than 5-10%. But in a poorly managed facility, the leaks account upto 35%.

80% of the leak spots in the system is inaudible. Conversely the largest leak repairs yields huge reduction in compressed air leakage quantity.

Fig (c): leakage identified in bag filter

(Ball joint)

Fig (d): Instrumentation inspection

(union joint)

We offer Ultrasonic Leak Detection Services to accurately identify leaks in compressed air systems, enhancing efficiency and reducing energy losses. Our expertise extends across various industries, from small manufacturing units and garment factories to large-scale cement plants.

Gas leak detection includes gases like :

- Argon

- Hydrogen

- Oxygen

- Nitrogen

Note: Our Leak Detection extends in identifying leaks in oxygen, argon and nitrogen lines as well.