Case Study-Power Quality

Repeated VFD Failures Due to Power Quality Issues in an Industrial Facility

Incident History

- The facility has faced multiple VFD failure issue in three machines which cause huge breakdown/losses in operation. The frequency of VFD failure was twice in a month randomly on these three machines.

- The plant has modified the circuit of the machine by introducing the contactor before the VFD to isolate the machine while heater was in ON condition, after the modification the frequency of the incident reduced to once in a month randomly in three machines.

Root Cause Analysis

- The facility is facing the frequent VFD failures issues in the machines of 250kW. The main agenda of the work is to find out the reason behind the failure issue.

- The cause of the tripping problems has been determined through power logging and visual investigation.

Case 1: Voltage Notches.

Voltage Notch’s has occurred in the VHT 4 and VHT 3 machines.

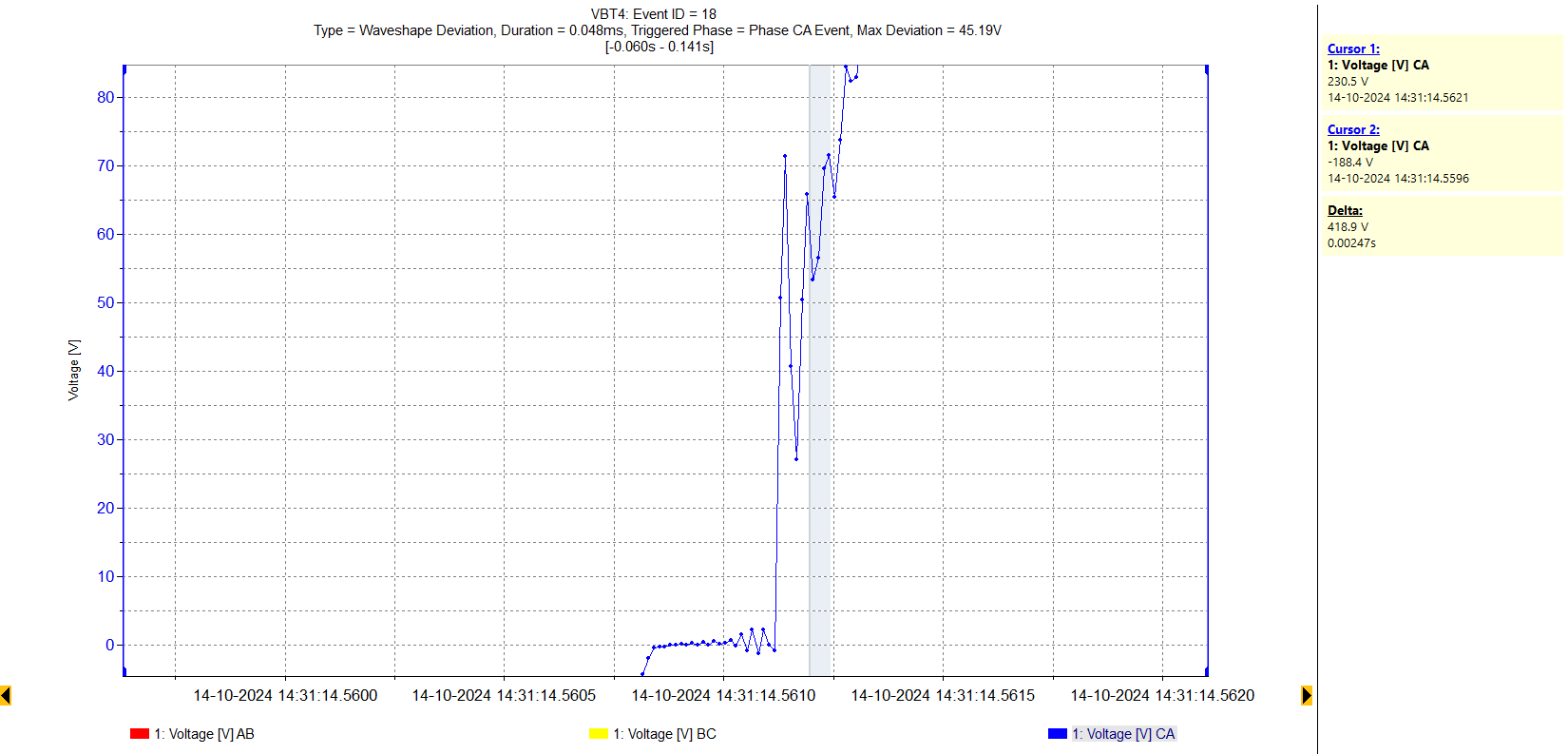

Voltage Notch in VHT 4 machine

Observation

VHT 4 motor was operating for 30 mins for each process once in 4 hours.

Total of 798 waveshape deviation occurred in the machine during the audit time in the 20 hours recording.

Voltage notch’s has occurred in each process cycles, and the range of voltage was 41 to 45V for the duration of 48 µs in each cycle of Voltages of CA.

Notch Depth (d/v) is more than 10% which is higher than the limit specified in IEEE 519 2022.

Reason Voltage notches occurred in the line as higher capacity VFD are operating with SCR based rectifier circuits, during commutation in the SCR when the current transferred from one conducting cycle to another it will cause phase to phase short circuit for very minute duration of microseconds.

Voltage Notch in VHT 4 machine

Case 2: Voltage Dip.

Voltage Dip occurred in VHT 4 and Voltage Dip.

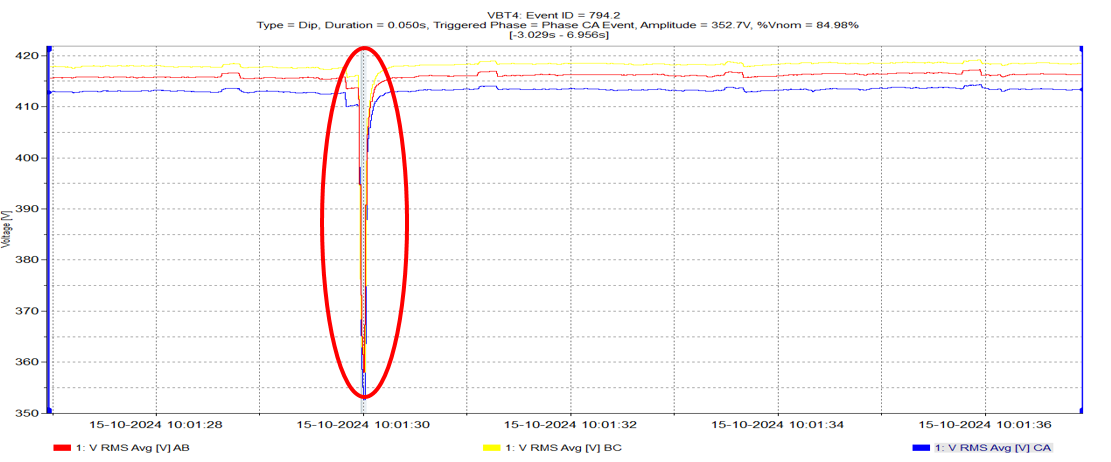

Voltage Dip in VHT 4 machine

Observation

Voltage Dip occurred 8 times during power logging in VHT 4 and it was not within the limit as per EN50160 standard.

Voltage has reduced from 415 V to 352 V for the duration of 0.05 seconds.

Reason 1: The voltage dip can be due to the sudden switching of higher load machines connected to the transformers.

Reason 2: Depending on the load on the VFD, a momentary voltage sag may cause the DC bus voltage to drop below the fault threshold. During the voltage sag (dip), the energy for the motor is drawn from the DC bus capacitor, causing it to drain quicker than usual. When voltage is restored (when voltage sag is eliminated), a substantial inrush of current from the AC input side occurs, charging the drive bus capacitors. This will damage the rectifier circuit and the capacitors of the DC drive.

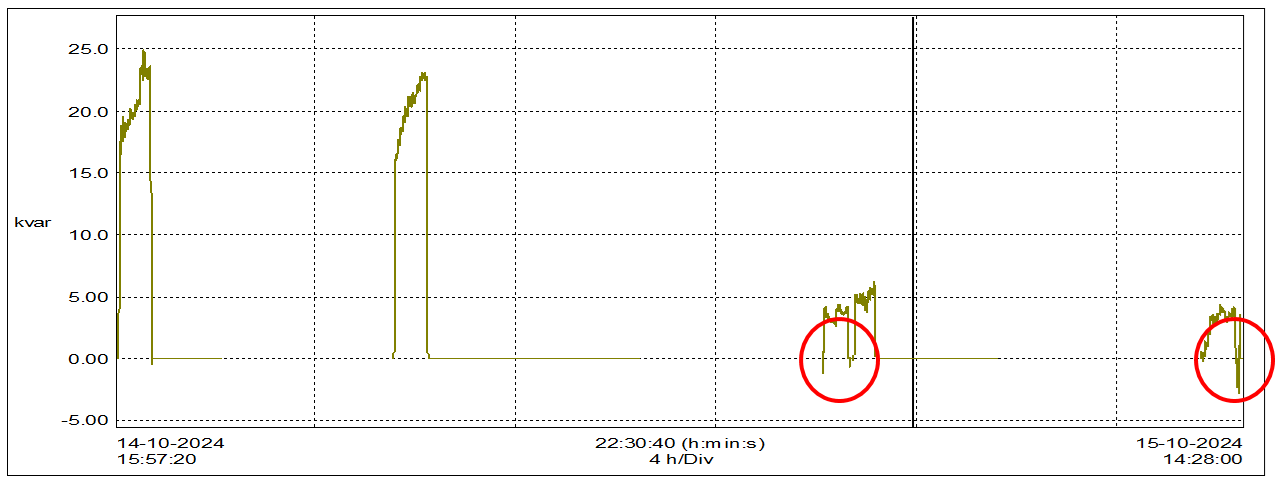

Case 3: kVAr injection during motor OFF

kVAr injection in VHT 3

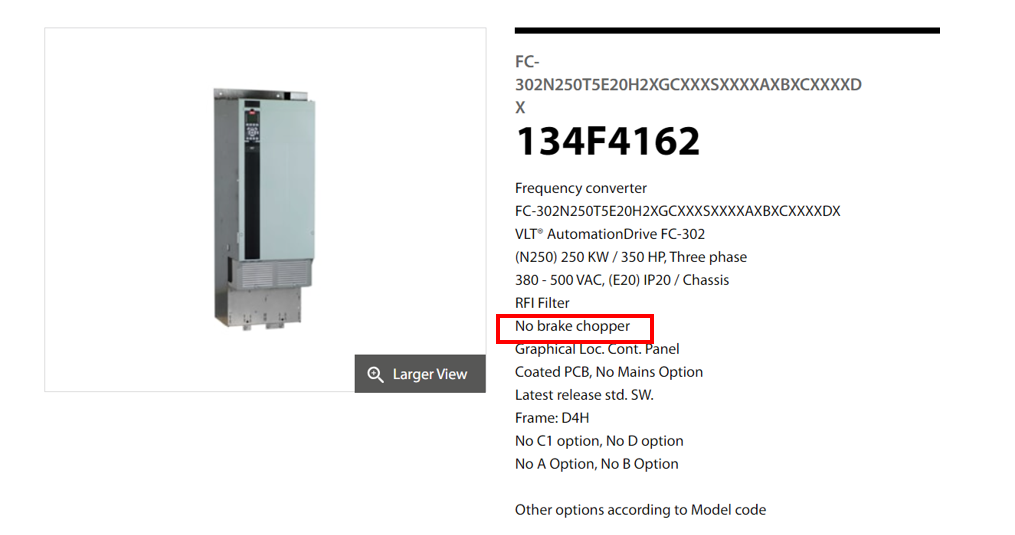

Specification of the 250 kW Danfoss VFD

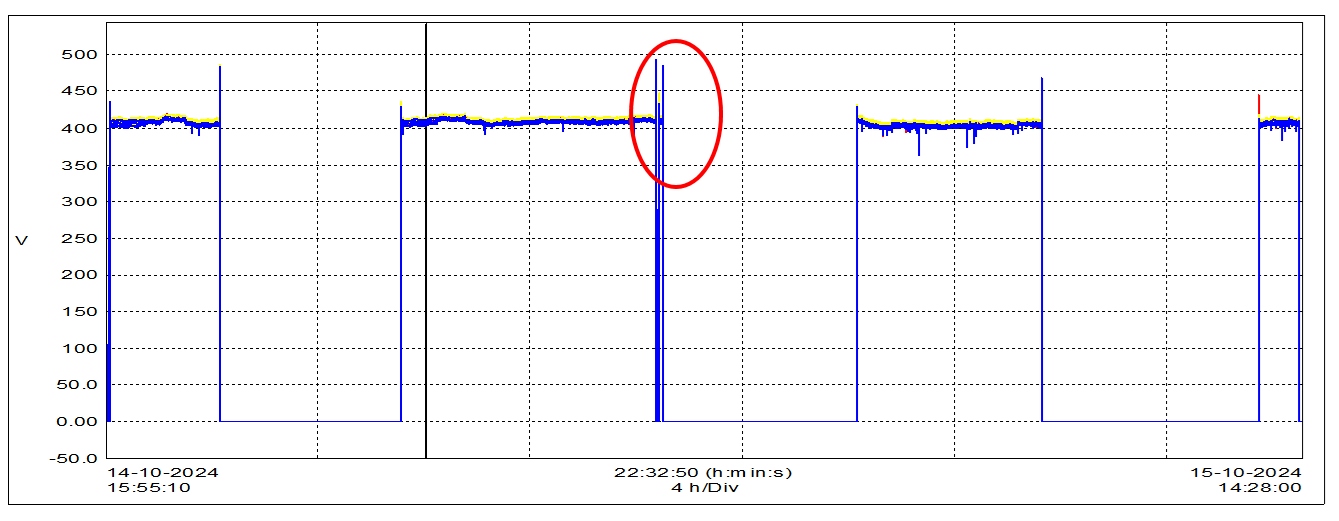

Change in voltage during voltage injection.

Observation

KVAr injection was observed in the VHT 3 and VHT 4 machines.

Brake chopper was not provided with the VFD.

Reason Regeneration occurs in the VFD when the motor OFF condition and runs for some time, and this excess voltage is added to the DC bus capacitor which can make the drive to fail.

Case 4: Current increase in VHT 3 during non operation

Improper current injection to the machine during non operation time.

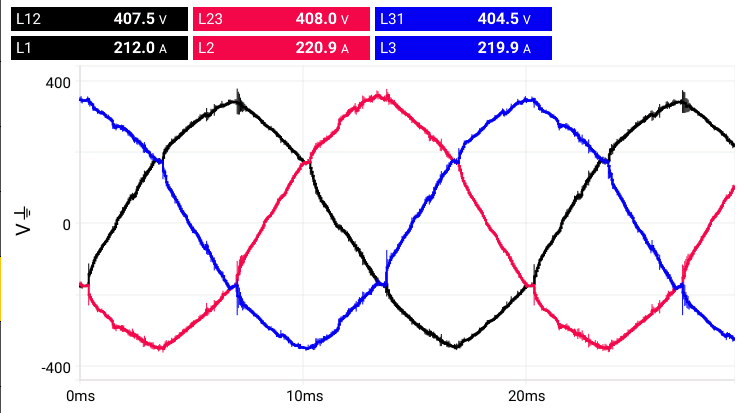

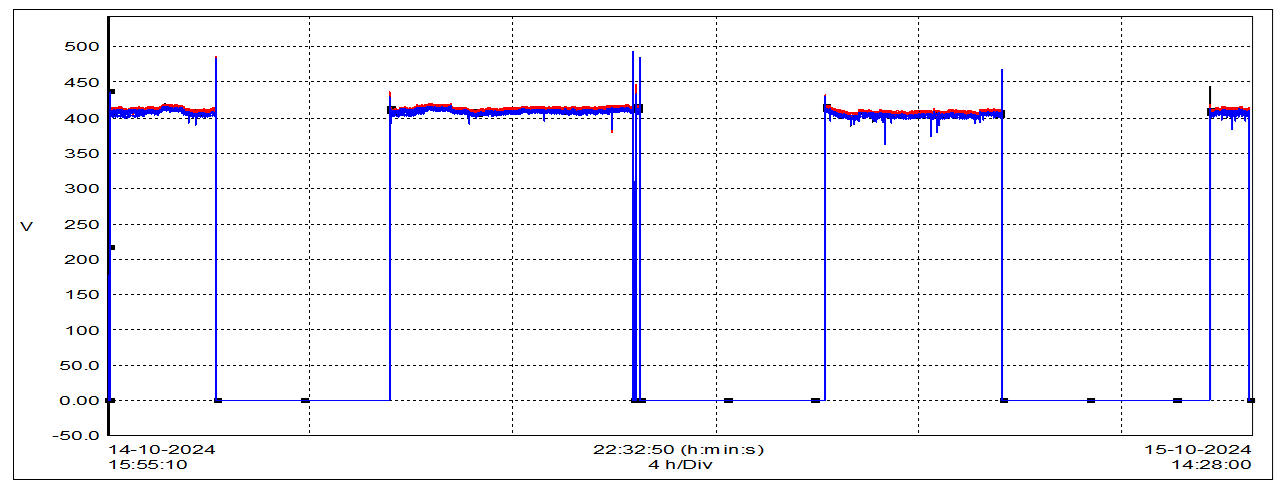

Voltage waveform of VHT 3

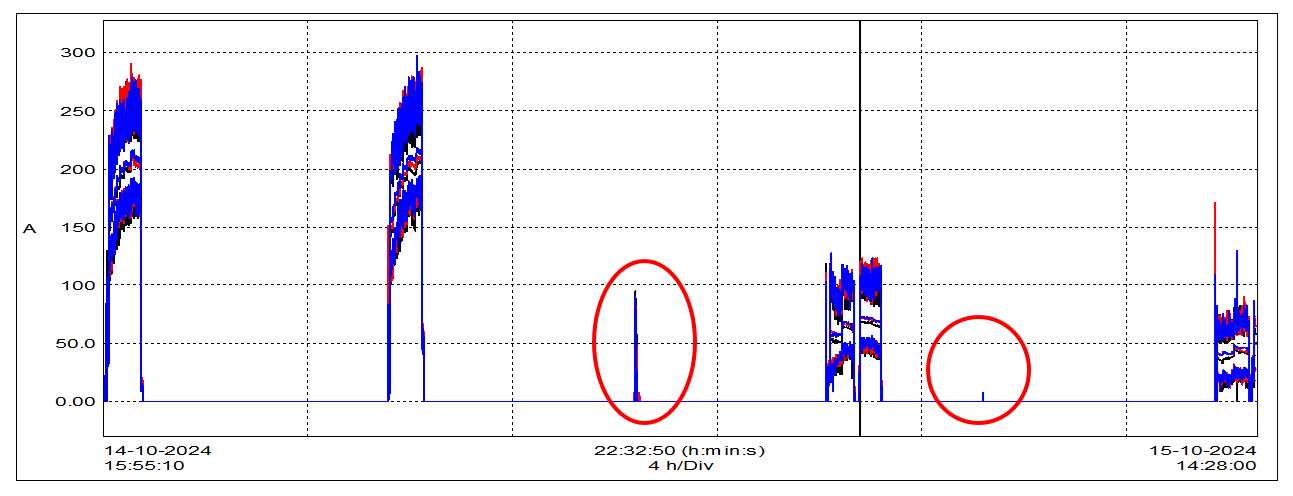

Current waveform of VHT 3

Observation

Voltage measurement was connected at the VFD input of the system after the contactor.

Contactor of the VFD was in closed condition even after the machine stops for the duration of 2.30 hours to 3.30 hours.

During the time of opening of the contactor, sudden increase in the current from 0A to 80 A for 3 seconds was observed during recording. This can damage the electronics components of the VFD.

Noise was observed during the opening and closing of the contactor.

Reason 1 : Sudden increase in the current during the time of contactor opening can be due to the contactor Arc and can be due to the increase in voltage due the time of contactor opening.

Reason 2 : Improper maintenance of the contactor can increase the voltage during the switching of the contactor.

Recommendations

- It is recommended to install a line reactor (Choke) with the reactance of 3% to reduce the voltage notches and voltage dip and regulate the input voltage of the VFD.

- It is recommended to install a Brake chopper and Brake Resistor to dissipate the kVAr injected during the free run of the machines.

- It is recommended to check the working condition of the EMC filter and insulation of the cable in VHT 3 machine.

- It is recommended to clean and maintain the contactor during the PM activity.