Arc Flash Study: Bigeta Energy Solutions is your dependable resource for complete energy solutions. We recognize the crucial importance of maintaining a safe working environment for both our clients and their workers as a responsible energy solution provider. In keeping with this dedication, we are pleased to present our unique Arc Flash Analysis Service, which is intended to guarantee safety and compliance at your plant.

What is an Arc Flash Analysis?

A thorough assessment of your facility’s electrical systems and equipment called an “arc flash analysis” will help you find any possible risks associated with arc flash events. When an electric current veers off its planned course, it creates an arc flash, which is characterized by an explosive release of energy that can result in serious injuries, equipment damage, and even fatalities. Your electrical infrastructure is thoroughly analyzed by our knowledgeable team to ascertain the degree of risk posed by arc flash accidents.

Why Choose Our Arc Flash Analysis Service?

- Expertise and Experience: Electrical engineers with experience and qualifications in power system engineering, IEEE 1584, IEEE 1584.1-2022, NFPA 70E, short circuit, device coordination, and arc flash investigations should carry out these studies.

- Compliance with Regulations: Employers are required by electrical safety rules to evaluate the risks connected to arc flash accidents at their facilities. By using our audit service, you show that you are committed to following these laws and safeguard both your employees and your company from potential legal repercussions.

- Risk Mitigation: For mishaps using arc flashes to be avoided, potential hazards must be identified. By assisting you in locating any gaps in or inadequacies in safety procedures, our audit service enables you to take proactive efforts towards effectively lowering risks.

- Customized Solutions: We are aware that every institution has different needs in terms of electrical safety. Our staff customizes the audit process to meet your unique requirements, making sure that all important areas are carefully scrutinized. We offer thorough analyses and suggestions so you may put specific safety measures into action.

- Cost Savings: You might possibly save a lot of money by using our Arc Flash Analysis Service and avoiding mishaps, equipment damage, and downtime. Early risk detection enables you to implement preventive steps, decreasing the possibility of expensive occurrences.

Exploring Arc Flash Studies: Critical Analysis and Implementation

An arc flash is a sudden release of electrical energy through the air, typically occurring when a high-voltage electrical current jumps across a gap in an electrical circuit.

This phenomenon can result from various factors such as equipment failure, insulation breakdown, or accidental contact with energized parts.

When an arc flash occurs, it generates intense heat, light, and pressure, creating a dangerous explosion-like event. Arc flashes pose serious risks to personnel safety, causing burns, injuries, and even fatalities, and can also damage equipment and infrastructure.

Understanding the Necessity and Scope of Arc Flash Studies

- Can you confidently ensure the absence of electrical accidents, particularly Arc-Flash incidents, in your workplace’s future?

- Is it feasible to avoid maintenance tasks on energized switchgear by implementing various forms of offline maintenance?

- Does your system operate at a voltage level below 208V?

If any of your answers to these questions is NO, then Arc Flash Studies are essential. It’s crucial to conduct an Arc Flash study before any worker is exposed to electrical hazards. Furthermore, it’s advisable to review Arc Flash risk assessments every five years or whenever modifications, such as changes in load or protective equipment, are made to the facility that could influence the study’s results.

Reference Standards:

- NFPA70E: Standard for electrical safety in the workplace

- IEEE Std 1584: IEEE Guide for performing Arc flash hazard calculation

- IEEE Std 1584.1.2022: IEEE Guide for the specification of Scope and Deliverable Requirement for an Arc-Flash Hazard Calculation Study in accordance with IEEE std 1584

Determining Arc Flash Incident Energy: Step-by-Step Guide

First, we must outline the study’s scope and deliverables in accordance with IEEE 1584.1:2022

The procedure to calculate incident energy and define Arc-Flash boundaries, as outlined by IEEE 1584:2018, involves the following steps:

STEP 1: Collect the system and installation data

The typical initial step in an Arc Flash Analysis involves collecting all existing electrical drawings i.e. single line diagram (SLD)available to the client.

In the absence of existing documentation, comprehensive electrical one-line diagrams must be created in the field, requiring a thorough field survey.

STEP 2: Determining the operational modes of the system

Single-line diagrams need to be created or revised to depict the current configuration and operational modes of the power system.

STEP 3: Calculate the bolted fault currents

A short circuit study is essential for assessing the current magnitude circulating within the power system at critical junctures during different time intervals subsequent to a fault event.

STEP 4: Establish typical gap and enclosure dimensions based on equipment classes and system voltages

If actual gap measurements from the installed equipment are available, they can be used. Otherwise, it’s necessary to stick to the values provided in the standard.

STEP 5: Determine the equipment electrode configuration

Data collection should include information available on-site. For instance, a panel board may contain both VCB and VCBB electrode configurations, while switchgear may have HCB depending on the bus and conductor arrangement.

STEP 6: Establish the working distances

Arc-Flash protection primarily focuses on the incident energy level affecting the head and torso at the designated working distance, rather than that on the hands or arms. Typical working distances are provided in IEEE 1584:2018 based on the equipment class.

STEP 7: Determining the Arcing Current

The total arcing current at a specific location is derived from the total bolted fault current available at that location. This calculated arcing current is usually lower than the bolted fault current due to arc impedance.

STEP 8: Establishing the Arc Duration

The arc duration refers to the period during which the upstream energizing source of arcing current ceases to supply current or energy to the arc fault. Usually, the clearing time of overcurrent protective devices is contingent upon the magnitude and/or direction of the arc current passing through their current sensing equipment (such as current transformers, relays, etc.)

STEP 10: Determine the Incident Energy

Incident energy calculations should be conducted at each switchgear, panel, and distribution board (DB) location defined to ascertain the highest magnitude incident energy or ‘worst-case’ scenario.

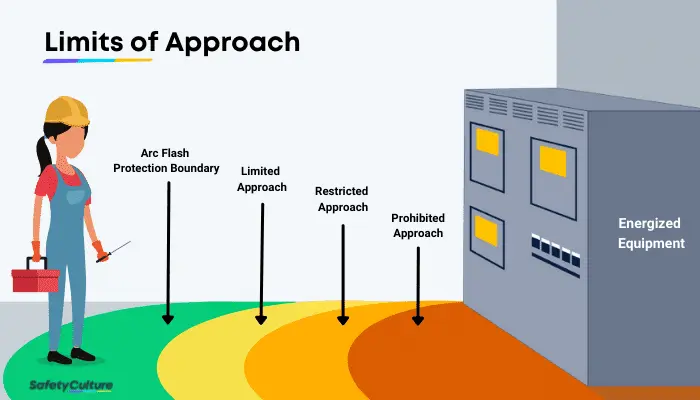

STEP 11: Defining Arc-Flash Boundaries Across All Equipment

The Arc-Flash boundary is the distance from a potential Arc Flash source where the incident energy is measured to be 1.2 cal/cm2.

STEP 12: Arc Flash Training

Comprehensive electrical safety training is essential for all personnel who may be involved in the operation or maintenance of electrical gear. This training serves as the final step in the Arc Flash Analysis process, ensuring that employees are equipped with the knowledge and skills necessary to safely handle electrical equipment and mitigate arc flash hazards effectively.

Exploring the Next Steps: What Comes Next?

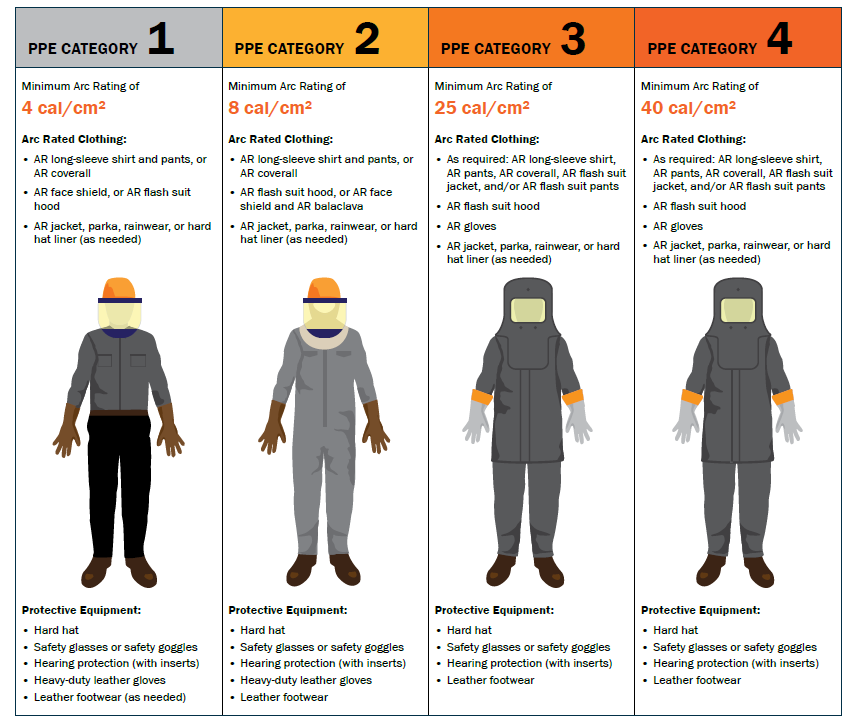

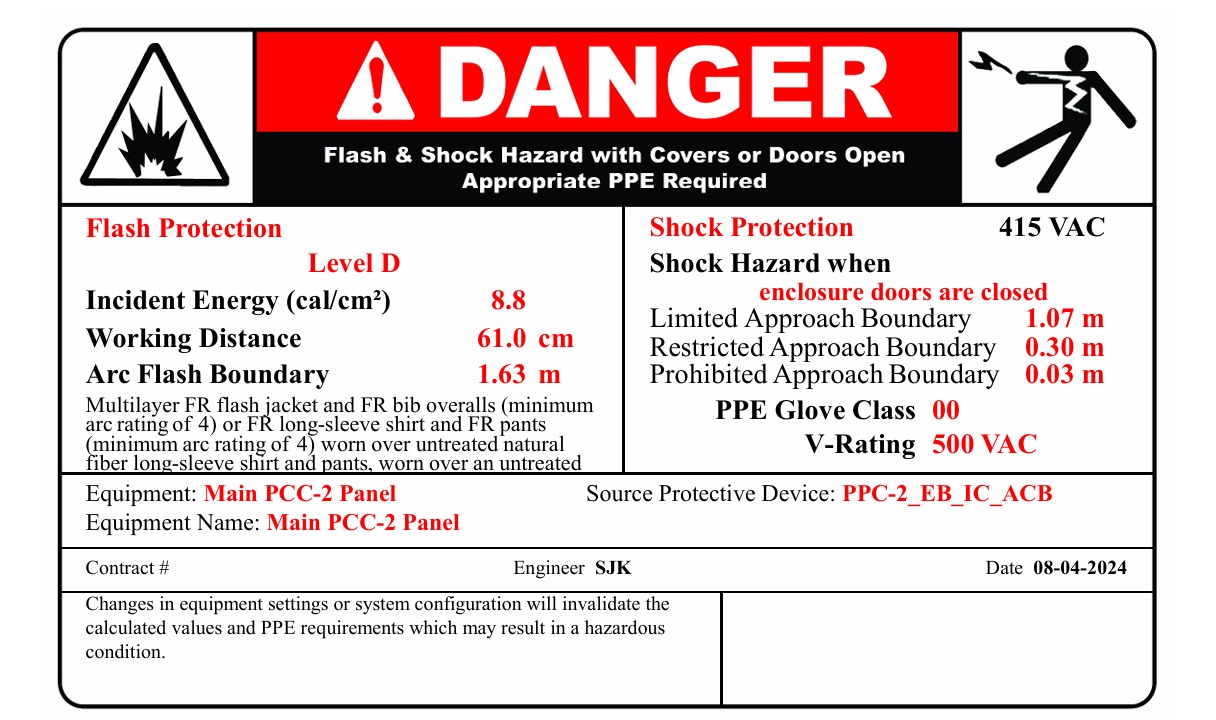

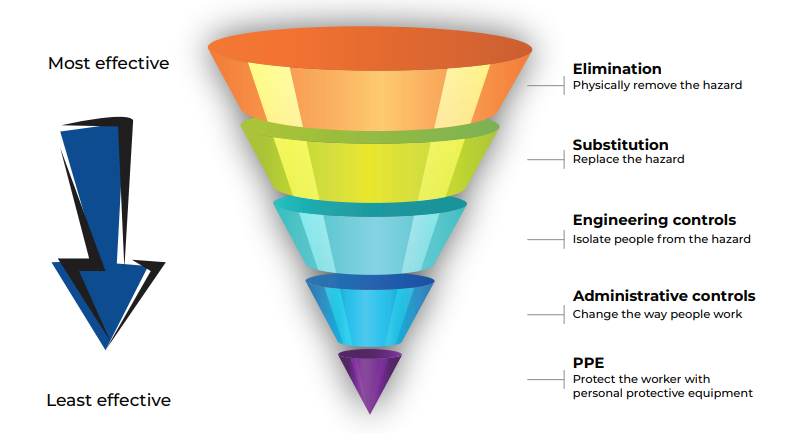

After calculating the incident energy and establishing Arc flash boundaries for all equipment, the study’s final results are important for selecting Arc-rated PPE and clothing with sufficient arc ratings. It is recommended to affix Arc Flash labels on the front side of every panel to ensure worker awareness.

Furthermore, marking the Arc Flash boundary and limited approach boundary in front of every panel, as per IEEE 1584 and NFPA 70E 2021 recommendations, is advisable for safety compliance.

Arc Flash Labels: Ensuring Safety Awareness:

Recommended Practice: Placing Arc Flash Labels on Panels Arc Flash labels should be affixed to the front side of each panel to enhance worker awareness.

These labels provide essential information such as Incident energy level, Working distance, Limited approach boundary, Restricted approach boundary, Arc Flash boundary, and recommended Arc Rated PPE

Arc Flash Mitigation

Myths Related to Arc Flash:

Dismissing the Possibility: “Arc flash explosions do not happen, Since I have never witnessed one, it is unlikely to happen to me.

Neglecting Analysis: ” Regular thermography of electrical equipment is sufficient for not conducting an Arc Flash analysis.”

Underestimating Risk: ” Arc flash incidents only occur in high voltage systems. Since I work with low-voltage equipment, I don’t need to be concerned about arc flash”

Overlooking Updates: ” Arc flash incidents only occur in high voltage systems. Since I work with low-voltage equipment, I don’t need to be concerned about arc flash.

Ignoring Safety Measures: “We do not engage in live work, therefore arc-rated PPE is unnecessary.

Simplifying Importance: ” Arc flash analysis is merely a process of labelling electrical panels.

Limiting Scope: ” The sole objective of an arc flash study is to determine personal protective equipment (PPE) requirements.”

Conclusion

Utilizing ETAP for arc flash analysis empowers engineers with a thorough understanding of potential hazards, enabling informed decisions to prioritize safety. By following the practical steps outlined in this guide, engineers can conduct comprehensive arc flash studies, strengthening electrical systems against potential risks. ETAP’s dynamic capabilities make it an essential tool for engineers engaged in arc flash analysis, ensuring the resilience and safety of power infrastructures. Unleash the power of arc flash analysis with ETAP for a secure and robust electrical environment